- Please consult customer service before purchasing!

- Our electronic labels require a base station for operation! Please purchase the base station separately!

- We only provide the interface; the system built into the base station does not handle business logic!

External interfaces are provided for integration with the customer’s system.

- The base station purchased by the customer is Version 1.4.

- The service software is directly integrated and pre-installed in the base station.

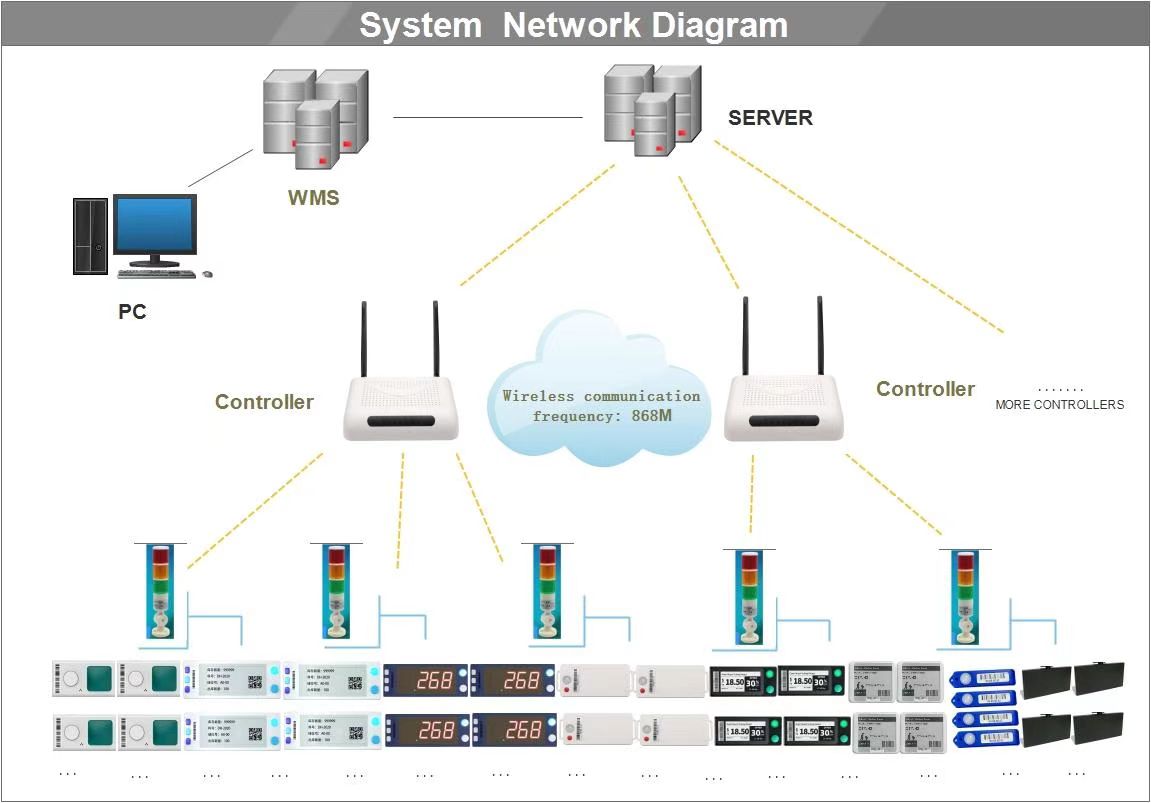

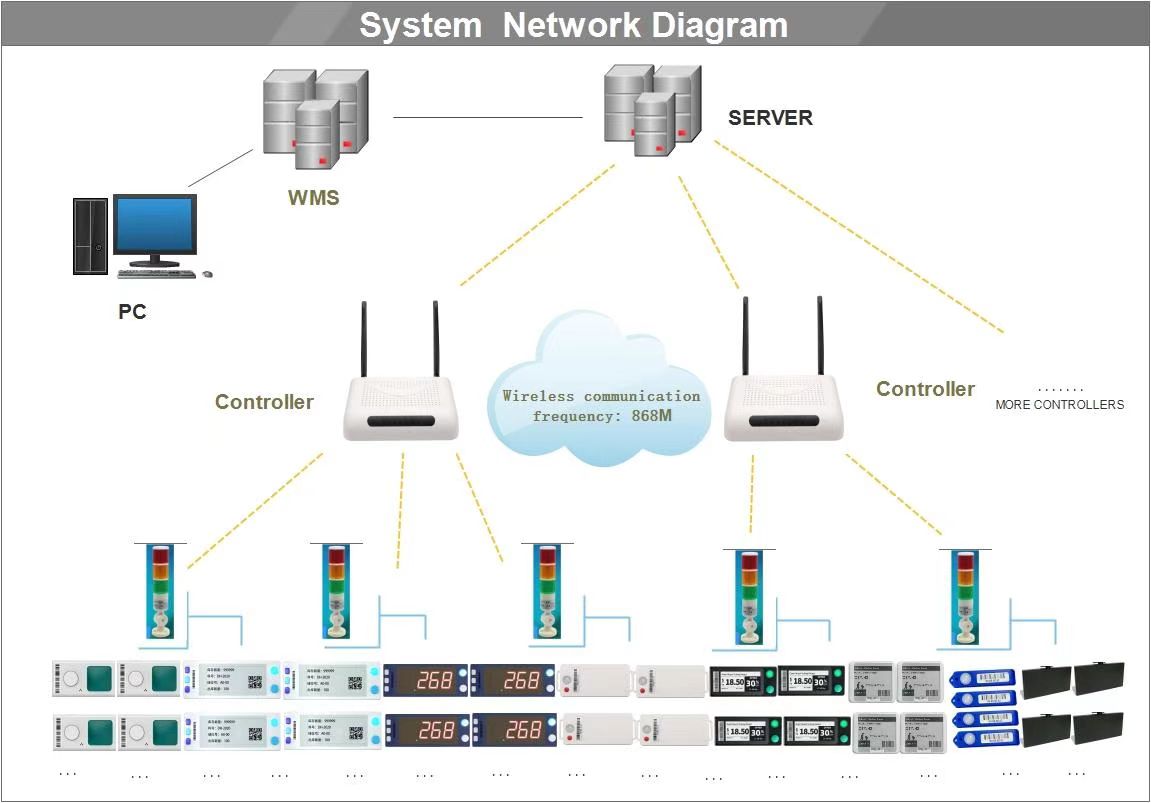

- The base station can connect to the local area network (LAN) directly, facilitating system docking via the interface.

- Ultra-low power consumption: Supports dual power supply modes (external power supply + built-in battery); wireless communication radius up to 30 meters.

- 868MHz wireless communication: Penetrates obstacles strongly, unaffected by barriers.

- Easy and fast deployment: No wiring required; supports data docking; flexible installation and movement.

- Custom two-way communication protocol: Safe and reliable; certified by RoHS and CE.

- Equipped with buttons and indicator lights: Guides staff in picking operations, improves work speed and quality, and shortens operator training cycles.

- Cost reduction: Lowers labor and management costs; enables paperless and standardized operations; makes picking smarter and inventory checking more convenient.

Suitable for scenarios such as shelves, logistics, warehouses, factories, and product classification, including:

- Warehouse light-guided picking: Improves work efficiency and clarifies material information.

- Put-to-light wall picking: After batch picking, allocates goods to orders (like "seeding" goods to respective orders).

- Smart material bin location: Electronic operations to enhance management efficiency.

- Smart paperless management: Paperless process from order placement to goods inbound/outbound; no paper printing needed.

- Wave picking with light guidance: Uses lights to distinguish different picking waves, solves wave separation problems, and improves wave sorting efficiency.

- Electronic material calling: Initiate material calls with a button; the whole process is timely and efficient to meet on-site needs.

- Light-guided picking (irregular scenarios): In warehouses with messy goods or irregular layouts, light-up labels solve the problem of difficult item locating.